Mengenal Cone Hydrocyclone, Salah Satu Alat Penting di PKS PT. Kharismapratama Abadisejatindo

The best-known hydrocyclone design model is Arterburn's model, also known as the Krebs model. Arterburn [] developed an empirical model that estimates the size and number of hydrocyclones required for a given comminution-classification operation.The method was developed for the normalized and standardized geometry of the Krebs hydrocyclone based on the company's experience with pilot and.

THE SIZING AND SELECTION OF HYDROCYCLONES By Semantic Scholar

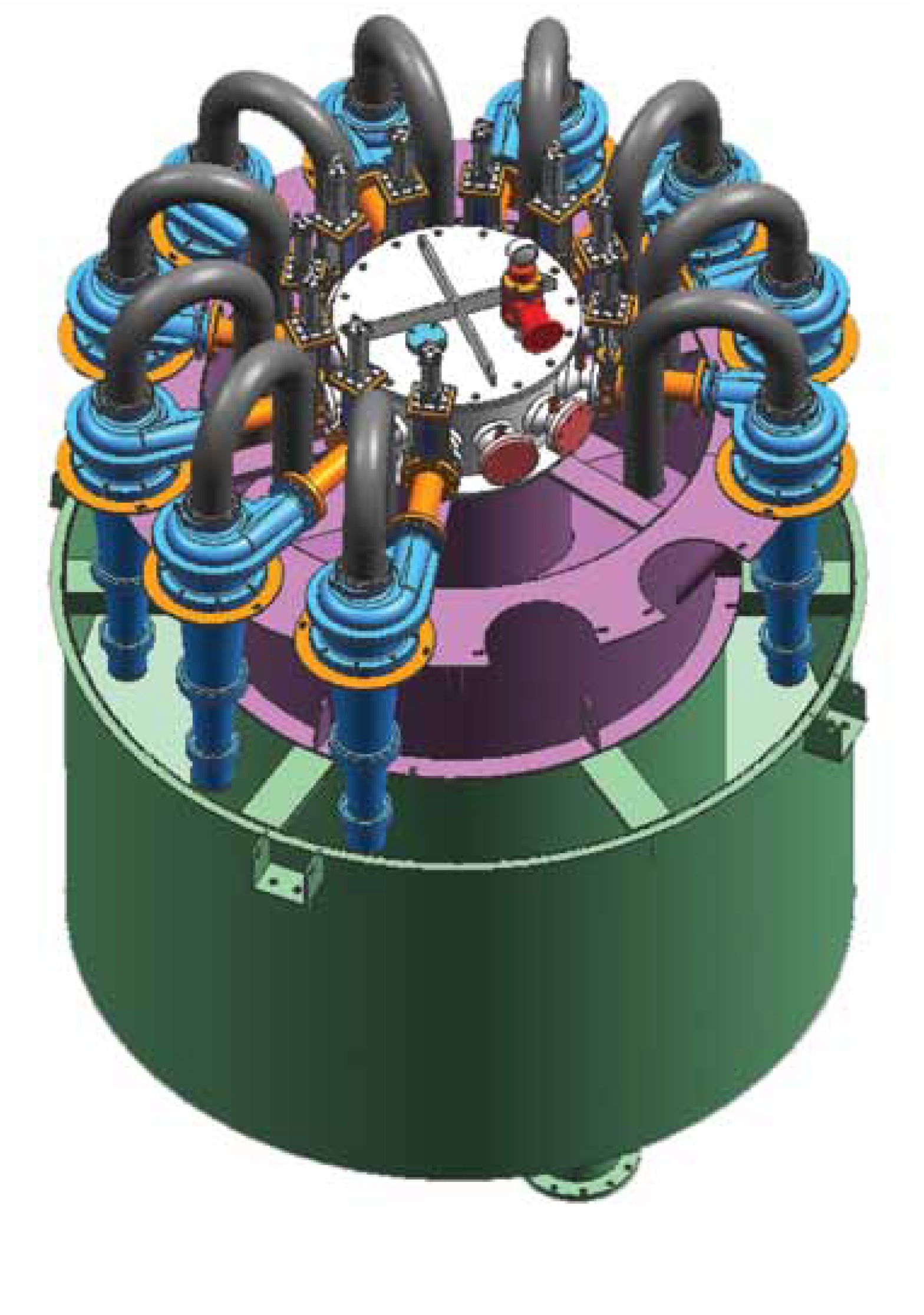

The Multotec hydrocyclone separator range consists of cyclone diameters ranging from 25mm to 1400mm, allowing them to accommodate a range of volumetric flow rates and cut size requirements. Different vortex finders, cone angles and spigot diameters are standard for all diameters. Hydrocyclones up to 100 mm (small diameter hydrocyclone) are.

Cross section of the hydrocyclone. Download Scientific Diagram

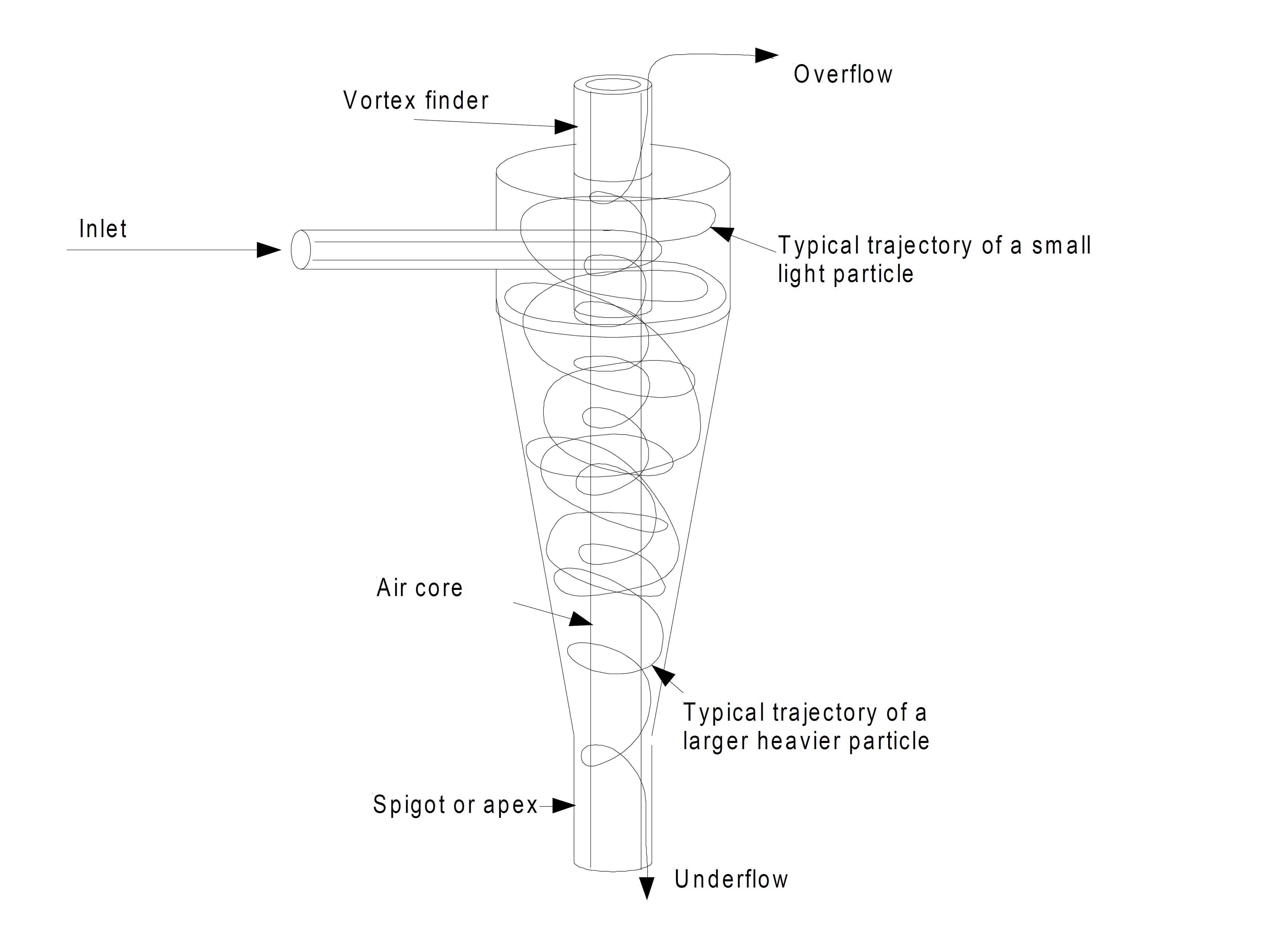

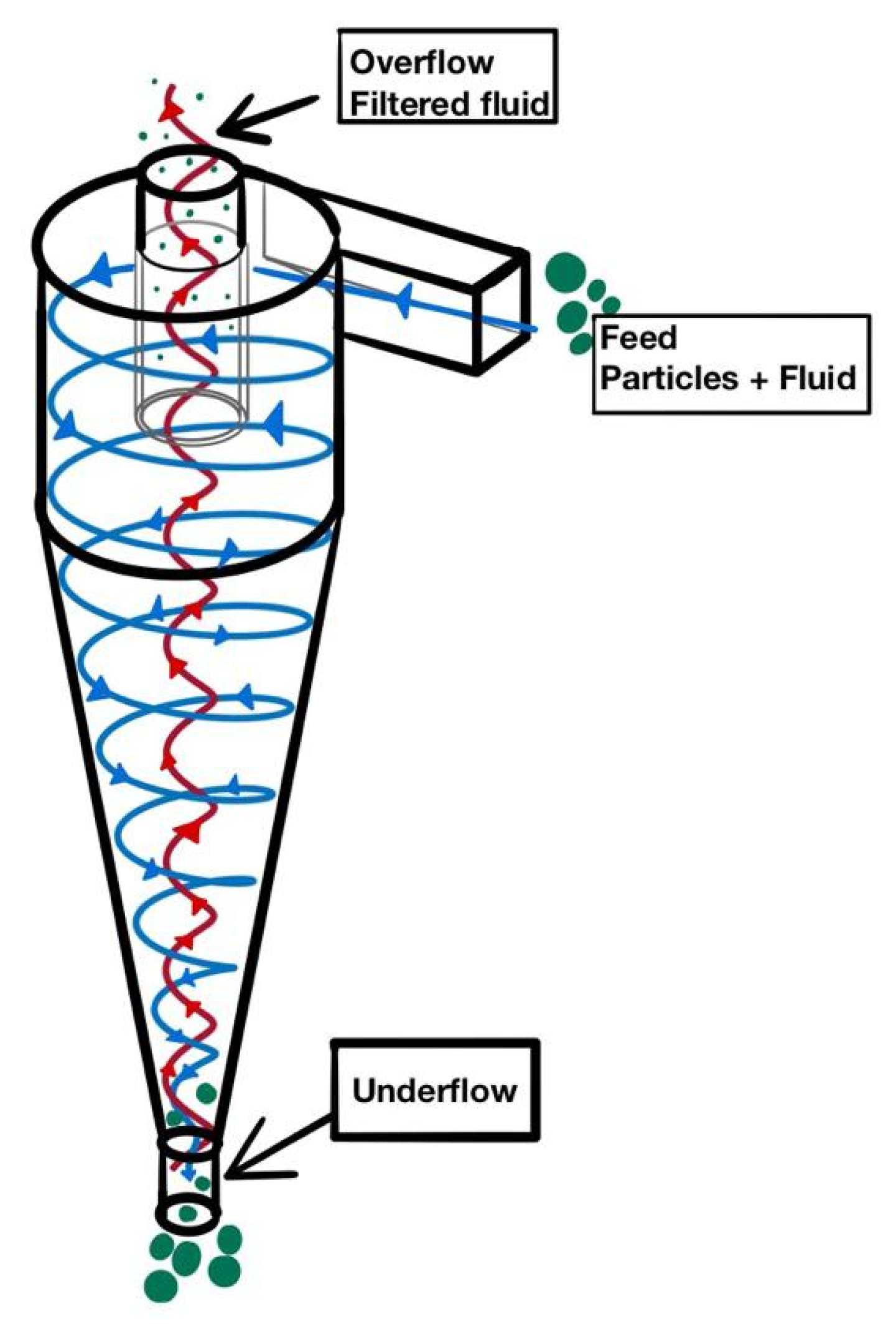

Hydrocyclone. A hydrocyclone showing the paths of fluid flow. Hydrocyclones are a type of cyclonic separators that separate product phases mainly on basis of differences in gravity with aqueous solutions as the primary feed fluid. As opposed to dry or dust cyclones, which separate solids from gasses, hydrocyclones separate solids or different.

Multotec hydrocyclones Australia

In the kernel hydrocyclone, the high over flow pipe is used to ensure that the ker nels entering are s ufficiently pure and ready for bagging. This high .

HydroCyclone Manufacturers and Suppliers in India

The capacity of the designed hydrocyclone system in volume is 5.5 liters. The developed machine was tested with 15 liters of palm kernel oil (PKO) as raw material using two different pressures gauge (70 and 80 kPa) and also effect acid concentration (sulphuric acid) at 3 different experimental runs.

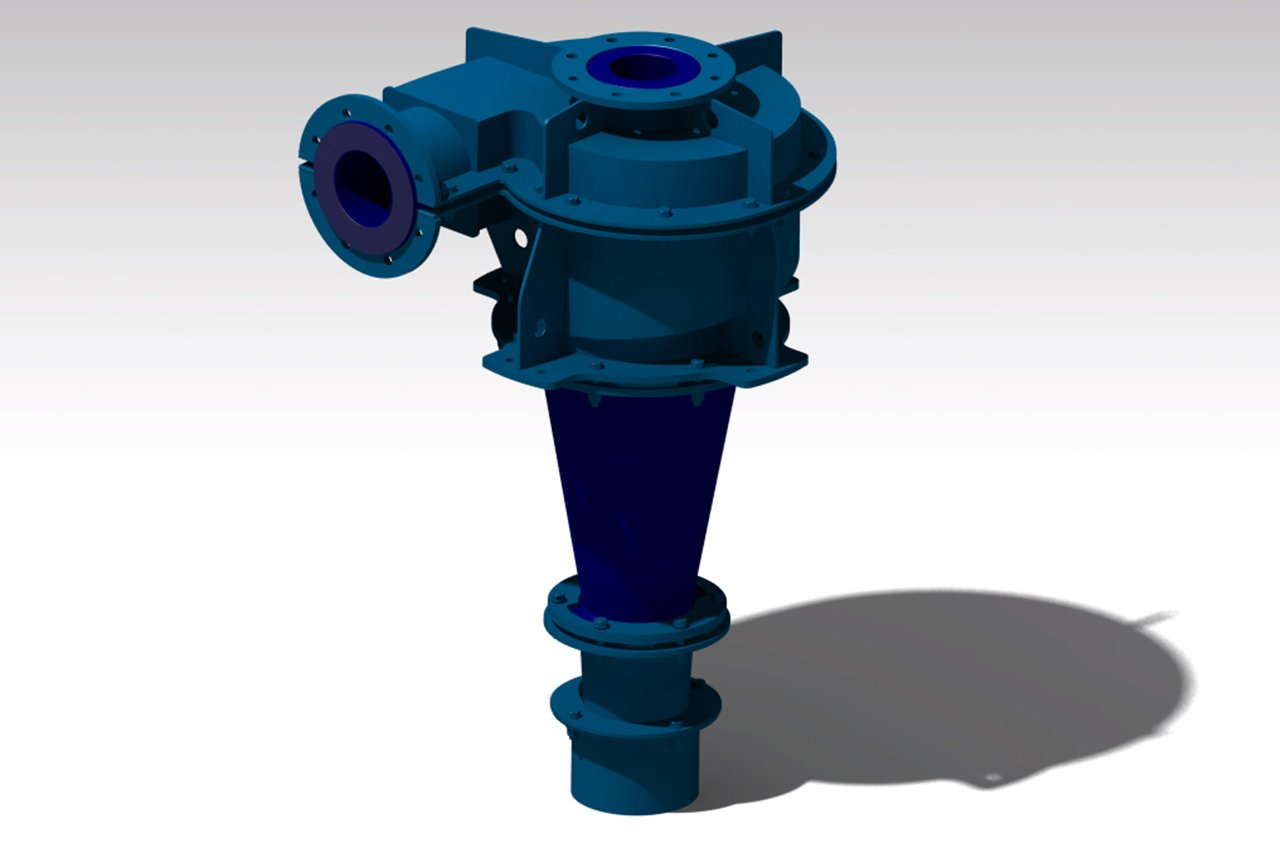

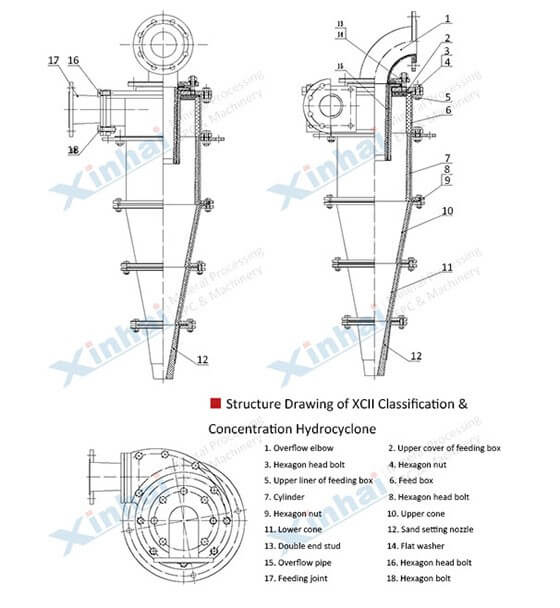

Hydrocyclone Assembly

The cracked mixture of kernels and shells was then separated in a hydrocyclone and claybaths. The third source of POME was fed from the wash-water of the hydrocyclone. The kernel produced was then stored into kernel bunkers before being transferred to the mill for oil extraction. Shell wastes were piled with the mesocarp fibers in the boiler.

Hydrocyclone technology basic Kivigrupp

The design computational results and/or specifications of kernel and. shell hydrocyclones and baths material balances and. other parameters, are tabularly presented. Keywords: Design, Hydrocyclone.

Schematic of the hydrocyclone flow structure. Download Scientific Diagram

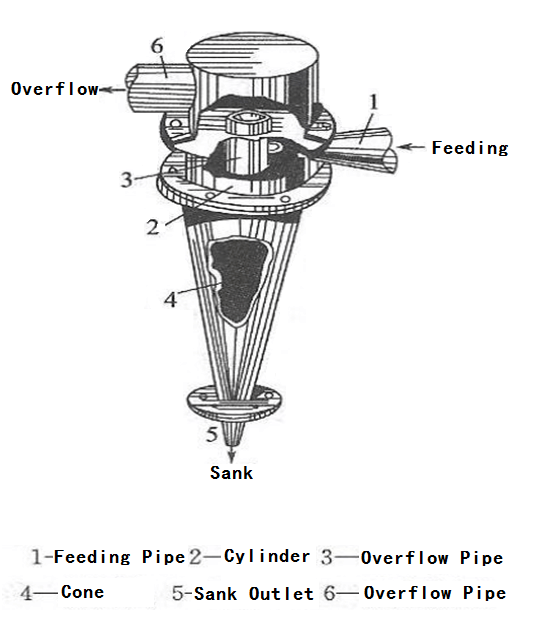

The hydrocyclone is a simple piece of equipment that uses fluid pressure to generate centrifugal force and a flow pattern which can separate particles or droplets from a liquid medium. These particles or droplets must have a sufficiently different density relative to the medium in order to achieve separation. The flow pattern in a hydrocyclone.

The construction of hydrocyclone. Download Scientific Diagram

Download scientific diagram | A diagram showing the cyclone action of a hydrocyclone. from publication: The adaptation of clay-bath and hydro-cyclone in palm nut cracked mixture separation to.

Schematic of a hydrocyclone illustrating internal flow structures as... Download Scientific

The number of shell containned in the hydrocyclone of this mill is achieved at below 1% and the line 2(B2) of hydrocyclone contain less dirt than the line 1. For the wet shell, the number of kernel loss (kernel, broken kernel, nut, split nut) also set at below 1% and the line 2 always contain more kernel than the line 1.

Schematic of a hydrocyclone and DGM. Download Scientific Diagram

The hydrocyclone separates palm kernel from shell particles by using of their proportion. The equipment list of palm kernel recovery station: 1.Cake Breaker Conveyor c/w Maintenance Platform&Supports 2. Nut Polishing Drum 3.Depericarper Column c/w Supports 4.Fibre Ducting's&Air Ducting 5.

Hydrocyclone technology basic Kivigrupp

PDF | On Mar 13, 2006, Kamalu, C.I.O. published THE DESIGN OF PALM KERNEL/SHELL SEPARATORS USING HYDROCYCLONE CONCEPTS | Find, read and cite all the research you need on ResearchGate

.jpg)

Hydrocyclone Technology Then and Now

Oil palm is now accepted as one of the most important oil-producing crops in the world. The bid to ensure efficient and quality production has resulted in the invention of machines that have greatly reduced human labour in the production process. Separation of cracked mixture to recover the kernels is one of the most important activities in Palm Kernel oil (PKO) production process. Research.

8 Technical Parameters of Hydrocyclone

kernel oil to be used in nonfood lipid sources for the production of bioresin, lubricants, chelating agents for metal extraction and other important chemicals [6,7].. separated using wet separation systems either by claybath or hydrocyclone [14]. The wet separation process of a cracked mixture is based on the differential specific gravities.

Hydrocyclone Working Principle

hydrocyclone and clay water bath. This experiment will investigate the best ratio of water and kaolin to achieve the best separation of the shell and kernel. The parameters investigated. kernel will started to float at Specific Gravity 1.08 and shell will start to float at Specific Gravity of 1.18. By drawing the graph of Separation.

Fluids Free FullText CFD Modeling of Hydrocyclones—A Study of Efficiency of Hydrodynamic

Population of Sousville, Auvergne-Rhône-Alpes, France: Current, historical, and projected population, growth rate, median age, population density, urbanization, and.