PCA Cement Grouting Process YouTube

The chemical grout is injected under pressure through the ports. The grout permeates the soil and hardens, creating a sandstone-like mass. The grouted soil has increased strength, stiffness, and reduced permeability. Chemical grouting offers the advantages of being easily performed where access and space are limited and no structural connection.

Grouting Process

REQUEST INFORMATION - OR - Ask A Question *Indicates a Required Field Grout under machine base plates is used to reduce vibration and maintain structural integrity. Call Epoxy for your next machine base plate grouting project!

Injection grouting system advantages, methods and applications

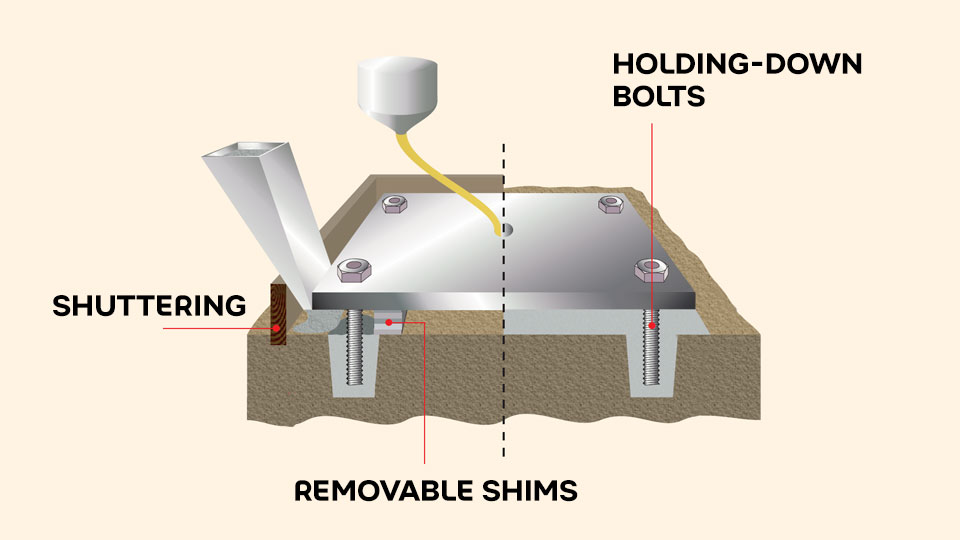

What is Machinery Grouting? Rotating industrial equipment and other types of heavy machinery, can't be simply installed onto a foundation or base. This is due to the irregularities in both the machine base and surface it will be mounted to; such as a concrete floor. It w ill create load-bearing issues and precision alignment difficulties that can become costly and dangerous down the line.

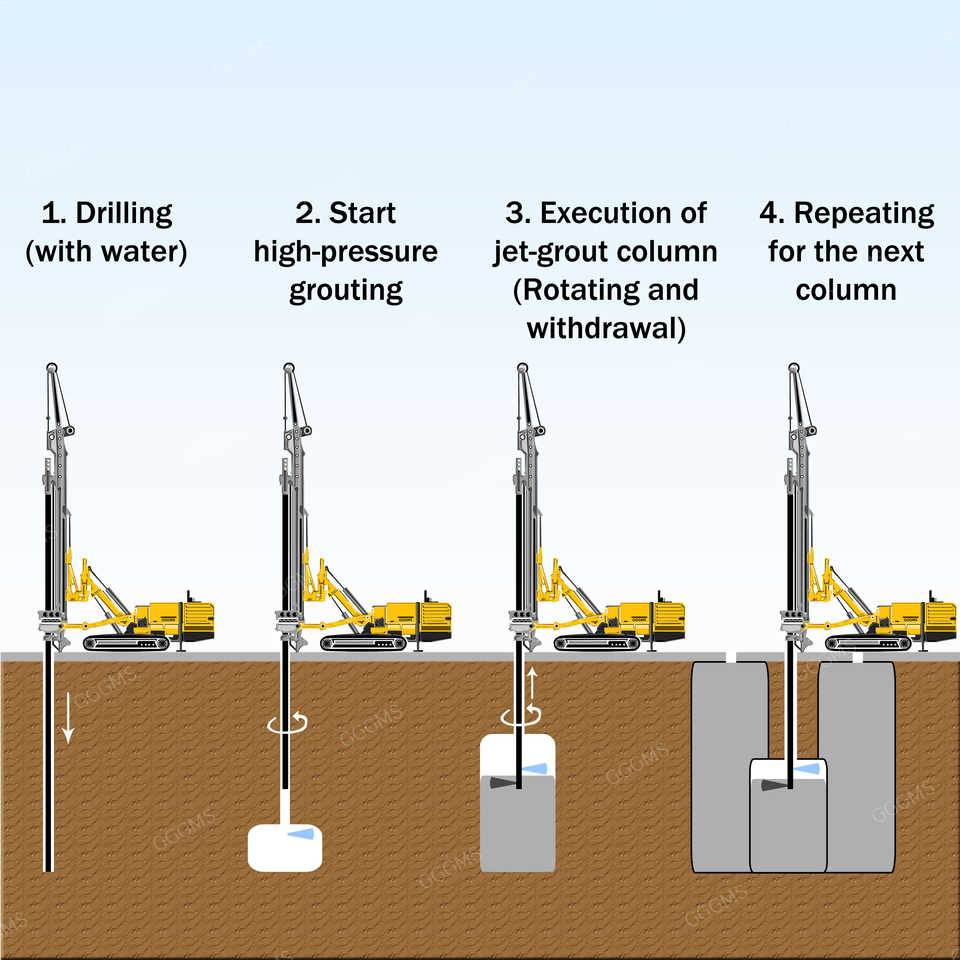

jet grouting construction method YouTube

The bentonite grout is pumped into the annular space through a tremie pipe that has been inserted to the bottom of the borehole along with the casing. The annular space between the borehole and casing is usually 2 inches or larger. This can vary depending on state regulations, depths and drilling conditions. Grouting is complete when the grout.

Grouting Process in Column YouTube

Column base plates. General machine base grouting. General grouting where the grout can be exposed to mild or moderate concentrations of many industrial chemicals. If required, the grout can be supplied with Sulphate-Resistant Cement. Most situations where a fluid, sanded grout is needed. Installing anchor bolts or tie rods. ADVANTAGES

Jet Grouting procedure Download Scientific Diagram

ARDEX ENDURA offers B 30, a cementitious non-shrink grout and B 50, high strength epoxy grout for grouting all kind of machines base plates. Following is the brief table explaining the properties of the grout which helps to select the grout quickly. Cementitious non shrink, expansive grout. B 31 - cementitious grout attains 10N/Sqmm in 10 Hrs.

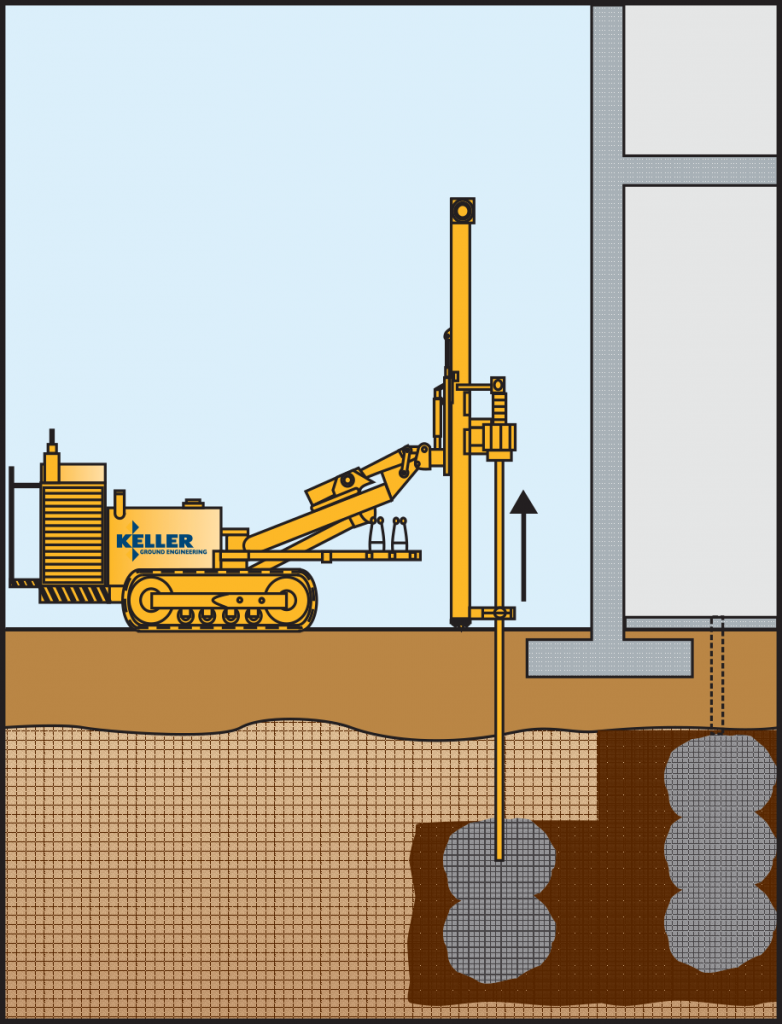

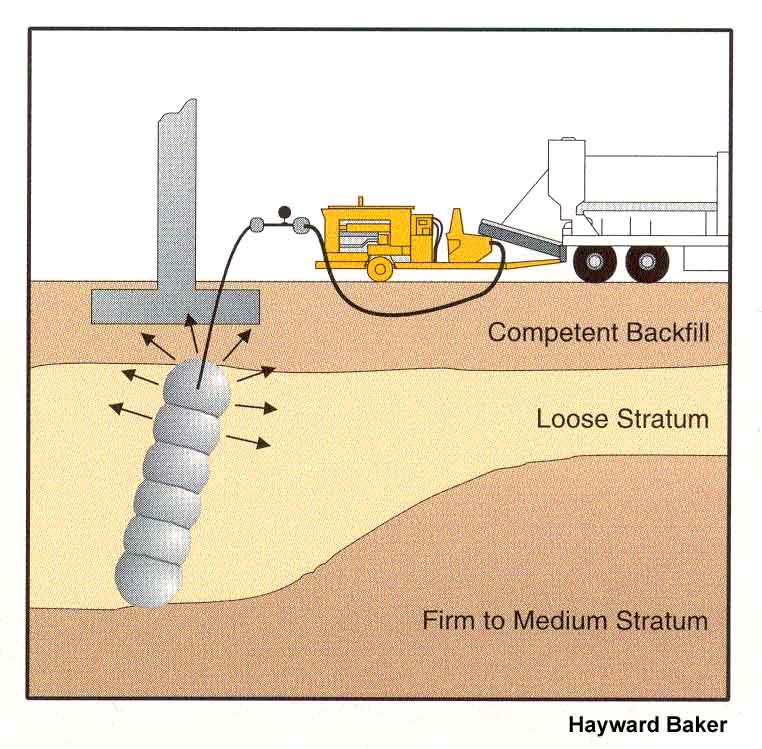

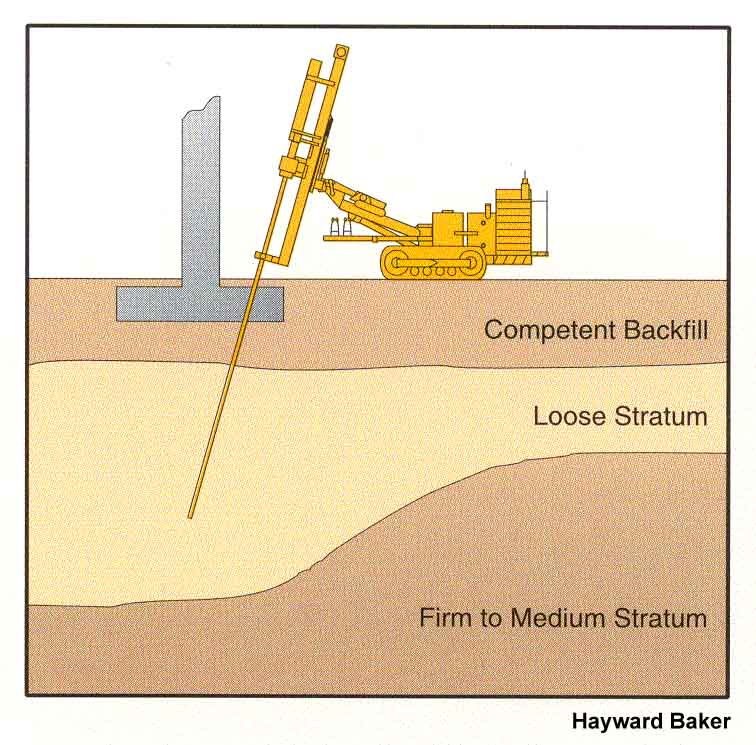

Compaction GroutingGeneral Geotechnical Photo Album

It is desirable to remove enough old grout from beneath the machine so that a load bearing area equivalent to a rail or sole plate mounting can be provided by the epoxy grout once it has been poured. If the foundation itself is cracked, it should be repaired before proceeding further.. Grouting Procedure for Low-Viscosity Epoxy Grout. 1. The.

(a) Illustration of the jet grouting method; (b) the jet grouting

Grouting Procedure for Equipment | Base Plate Grouting Purpose: These recommended practices (PIP) are intended to provide recommended procedures, practices and checklist for the installation and pre-commissioning of new and reapplied machinery for petroleum, chemical and gas industry services facilities.

Compaction GroutingGeneral Geotechnical Photo Album

Grouting is the process in which materials are injected into cavities or cracks in concrete, masonry structure, soil, and rock mass to increase the structure's load-bearing capacity refer to grouting, and the material used for this process is called grout.

Jet Grouting Geo Grout Ground Modification Specialist, Inc.

6.6—Safety and handling of epoxies Grout—A mixture of cementitious materials and water, with or without aggregate, proportioned to produce a pour- Chapter 7—Grouting procedures, p. 351.1R-14 able consistency without segregation of the constituents; also 7.1—Consistency a mixture of other constituents (such as polymers) with a 7.2.

Grouting steel baseplates

What Is the Machine Base Plate Grouting Procedure? Properly grouting a sole plate involves the following steps: Preparing the surface of the concrete and the sole plates. Before installation of the grout, the surface of the concrete and the plate must be adequately prepared.

Grouting Techniques Geotechnical Engineering

Grouting Procedures 1. Drill Ports Drill short holes, which is also known as ports, into the cracks/ openings in order to be used as entry and venting terminals. Minimum diameter and depth of ports are 2.5cm and 5cm, respectively. Spacing between holes is 150 mm c/c for finer cracks to 300 mm c/c for others.

GROUTING YouTube

Grouts are used for different applications like repairing of cracks, filling voids and gaps in tiles, sealing joints for waterproofing of the submerged structure like tunnels, canals etc. and for soil stabilization. Here we are discussing types of grout used for crack repairing. Types of Grouting Based on material, grouts are classified as follows:

Grouting of bases using dura.grout cementitious grouting • abe

Injection grouting is the method of filling the cracks, open joints, voids, or honeycombs, in concrete or masonry structural members. This is done under pressure with a grout material that cures in place to produce the desired results like strengthening a structure and preventing water ingress.

Injection, Grouting and Membrane Works CKTech Ltd

A proper foundation with machine grouting will keep the equipment running longer, while requiring less downtime for maintenance and repairs.. Most grout manufacturers offer specific recommendations on the proper underside preparation materials and procedures. Though cementitious grout was often used in the past, epoxy grouts are now more.

What is injection grouting Purpose Types Procedure Definecivil

This procedure utilizes an air-powered diamond coring machine, as illustrated in FIG. 7. Because the machine is air powered, it can be used in hazardous environments without creating a danger from sparks of open electric motors.. If any movement exists between the machine and grout, oil will penetrate voids caused by the movement, and.