Bending Steel YouTube

It involves the permanent plastic deformation of a sheet material along a straight or curved line. Bending involves a mixture of compressive (on the inner face) and tensile (on the outer face) deformation that may involve some significant local extension/stretching.

Locating a Man of Steel to Help with your Steel Bending The Chicago Curve

Bending HSS requires high-quality tooling made from steel that can withstand the high amount of force that is generated when bending these materials. Since the early 1980s, sheet metal fabricators have, for the most part, been following a pretty basic set of rules when it comes to air bending mild steel. To determine the appropriate die opening.

Bend test for steel

Preparing Your Steel. When prepping your steel for bending, make sure that it's free of any dirt or rust that could interfere with the process. Cleaning your steel with sandpaper or a wire brush is recommended before beginning. Once clean, measure out your desired length and width so that you have precise measurements for when you begin bending.

Precision sheet metal bending and the V groove

For example, the allowable bending stress of structural steel is calculated by multiplying 0.66 and the steel yield stress. Likewise, the allowable bending stress of various species of structural wood is between 1000 to 600 psi. You can design a beam by the following steps: Choosing a steel grade and allowable stress.

Fabrication of Steel EMR STEEL CONSTRUCTION

BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at 50 percent of the material thickness. In Machinery's Handbook, the K-factor for mild cold-rolled steel with 60,000-PSI tensile strength is 0.446 inch. This.

Industrial History Bending Steel Beams

Rolling (cold bending) is the typical method of curving steel for con-struction and is usually the most economical for rolling members with tighter radii. A steel member is placed in a machine and curved be-tween three rolls. Cold bending may also be called "pyramid rolling" because of the three rolls' pyramid arrangement.

Steel bending & Forming Queens, Jamaica Omni Steel Supply

'Air' bending refers to the gap left above and below the material at full bend depth. Bottom bending also uses a punch and bottom v-shaped die but bends the metal by bringing the die and punch together. Because the material is pressed into the bottom of the die, the desired bend angle determines the specific die to be used.

Bending Steel Monochromia

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. [1] Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses.

Bending Steel Prologue, Alt. View by Sleeper77 on DeviantArt

Bending. In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of.

Bending highstrength steel

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece. The force must exceed the material's yield strength to achieve plastic deformation.

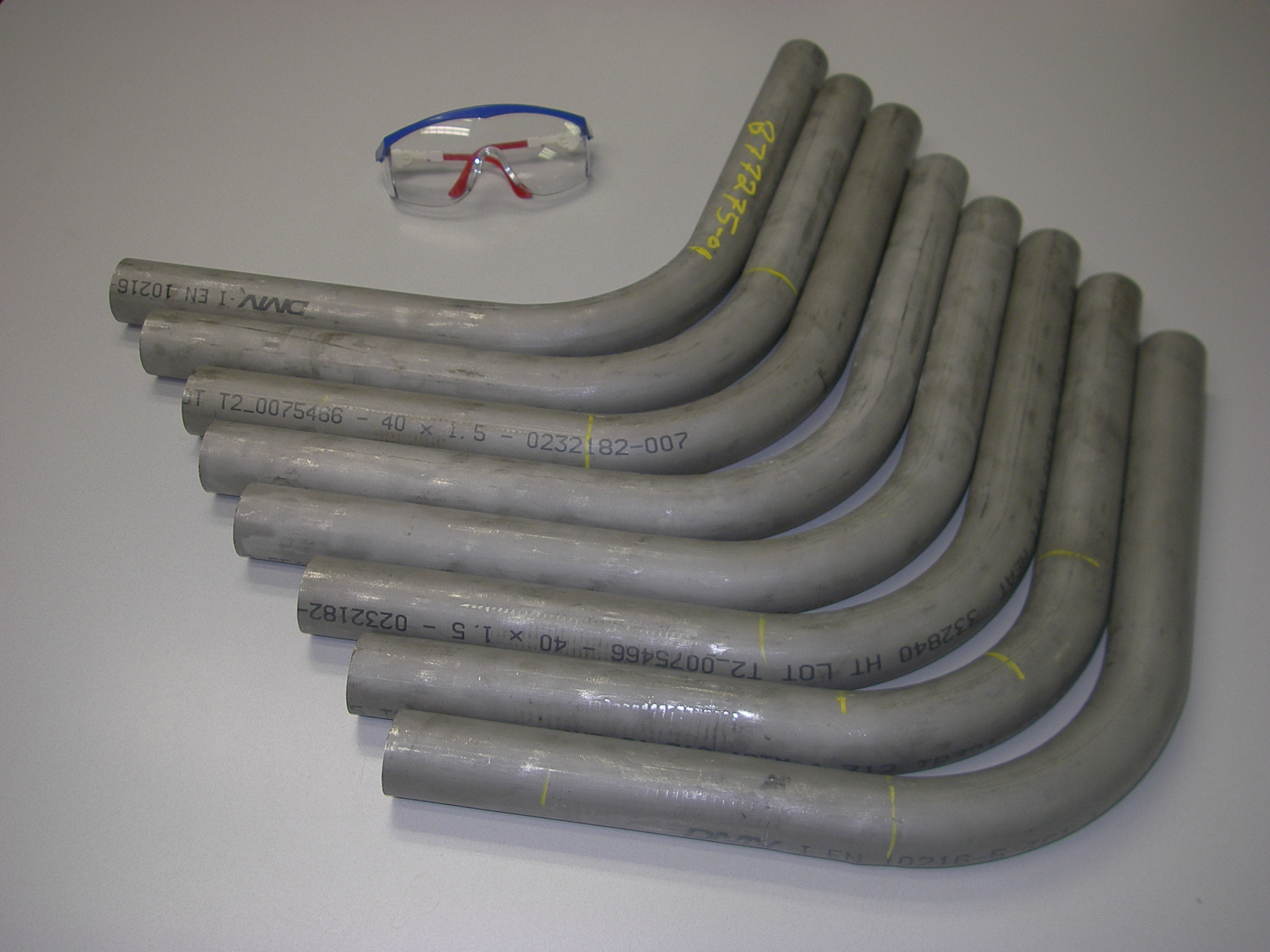

Bending Steel Tubes Curved Structural Steel Chicago Metal The

Sheet metal bending is an operation that involves using forces to change the shape of a sheet. This is done to achieve the desired form or shape needed for a manufacturing process. The external force used alters only the external features of the sheet. However, parameters of the one type of sheet metal such as length and thickness remain the same.

Cut & Bend Steel Bar Company in India Friends Steel

The Steel Construction Institute, Silwood Park, Ascot, Berkshire, SL5 7QN. Telephone: +44 (0) 1344 636525 Fax: +44 (0) 1344 636570. The Section on General Design Data includes bending moment diagrams, shear force diagrams and expressions for deflection calculations. A variety of beams and cantilevers with

Metal Bending & Stretch Forming BendTek Inc. Metal Work & Fabrication

Bending/rolling steel is the process of curving a steel member to a specified radius and arc length. Bending is commonly used to describe the process for a tighter radius bend, whereas rolling is used to describe a larger radius bend.

Precise Metal Bending Services By Elemet Manufacturing

By Steve Benson Updated February 1, 2023 January 2, 2014 Article Bending and Forming Figure 1: A plate's grains run parallel to the rolling direction. While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more.

Common Mistakes To Avoid When Bending Metal

Bending strength or flexural rigidity is the ability of a work piece to withstand bending stress. The flexural strength depends on the failure load, effective length of the work piece and the dimensions of the cross section of the beam. Mathematically the bending strength is given as- σb = M.y/I where,

Bending Stainless Steel Tubing Mandrel Tube Bending The Chicago Curve

By Team Xometry September 8, 2023 11 min read Sheet metal bending is the process of applying a force to a sheet of metal to produce a radius. The most common way to achieve this is a press brake. This process can be used in the manufacture of vehicle body panels, fridges, electronic casings, and brackets.