Jishu Hozen (Autonomous Maintenance) PDF Belt (Mechanical) Lubricant

Volumen 7 -201 9 a SEISO en Jishu -Hozen (lectura final). Title of English Version: Factory Management - TPM Total Preventive Maintenance. Volume 7 -201 9 a SEISO in Jishu -Hozen (final lecture). Now 12 steps start at once. 44 Agree with the world with disagreement 51 Diversity of opinion 52 Listen the customer's needs 53 TPM Checklist 55.

Jishu Hozen Implementation Steps Landscape Wall Sign

Chapter 5. Jishu Hozen Manual - View presentation slides online.

TPM TPM Jishu Hozen and Clti PDF Science Science And Technology

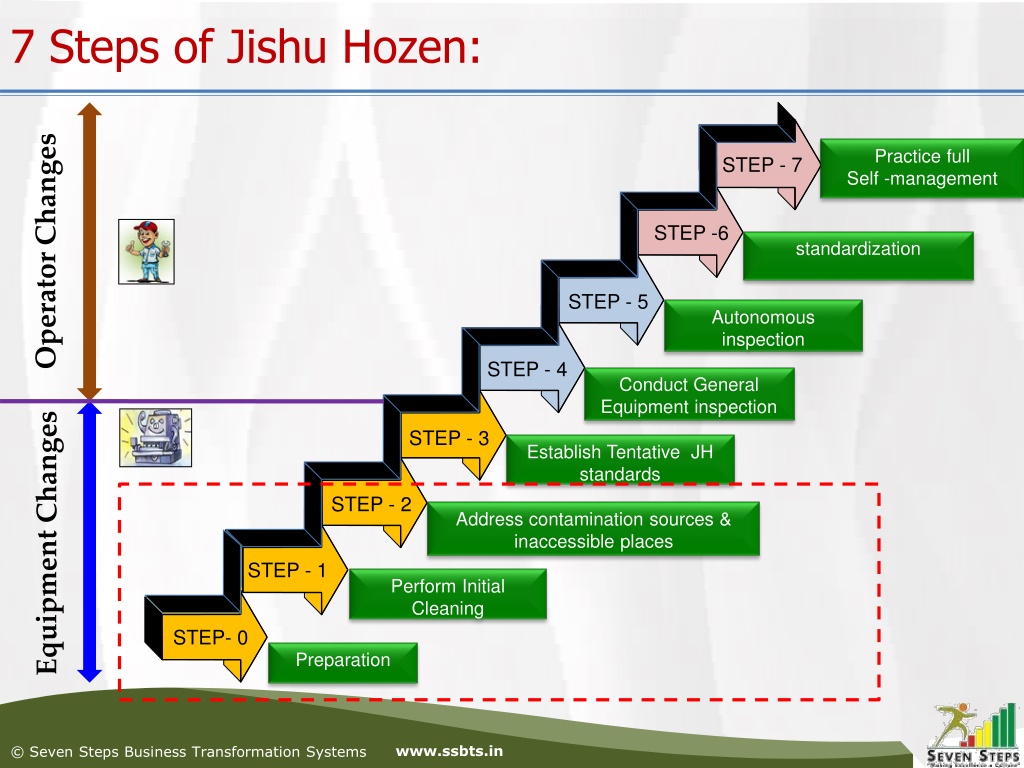

7 Steps of Jishu Hozen (Autonomous Maintenance) Pillar in TPM. 7 QC Tools for Process Improvement | PDF | Case Study. 5S in the Workplace | 5S Implementation | 5S Meaning | PDF. Problem Solving Methods | Steps, Process, Examples. Categories. 7 QC Tools (8) Control Chart (3) Difference (9) FMEA (3) General (12) IATF 16949 (4)

Step of "JishuHozen "Activities Japanese Gemba Kaizen Web PDF Reliability Engineering

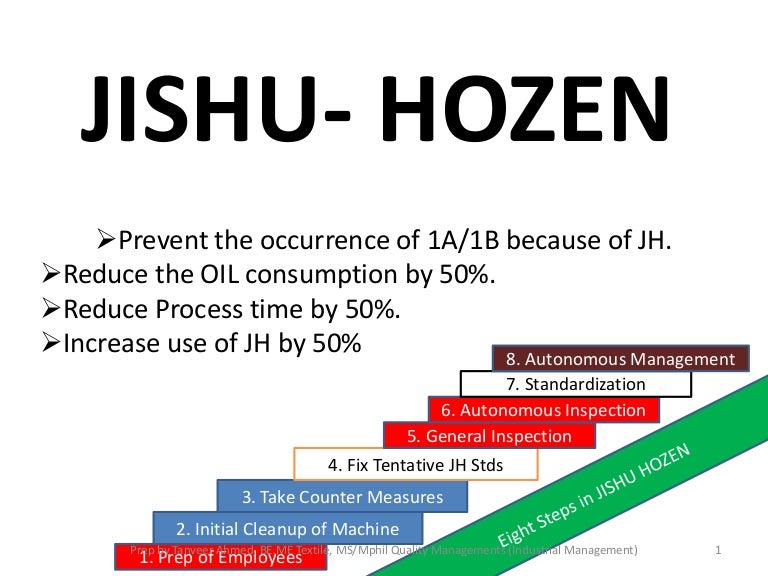

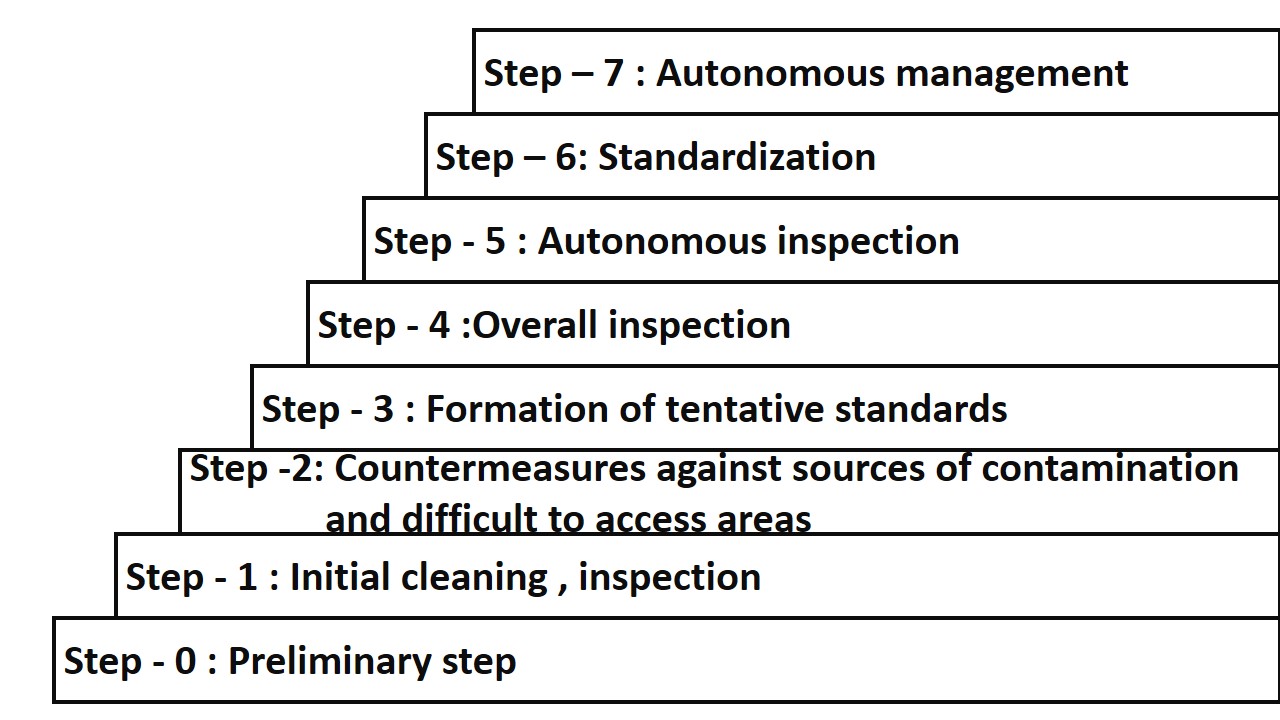

Jishu Hozen is a Japanese word that means autonomous maintenance. "Jishu" loosely translated, means - independence, autonomy. "Hozen" when translated to English means - preservation, integrity or conservation. Jishu Hozen is one of the eight pillars of Total Productive Maintenance, the other seven being: Focussed Improvement.

TPM 7 Steps of Autonomous Maintenance (Jishu Hozen) Poster (3page PDF document) Flevy

TPM-7 Seiso in jishu-hozen (final lecture) - Download as a PDF or view online for free. TPM-7 Seiso in jishu-hozen (final lecture) - Download as a PDF or view online for free. in a company. 31 TPM Introduction in Gemba 31 TPM Introduction in management 35 ADKAR process 38 Gemba-Ryoku 42 Now 12 steps start at once. 44 Agree with the world.

การบำรุงรักษาด้วยตนเอง AM Autonomous Maintenance / Jishu HOZEN

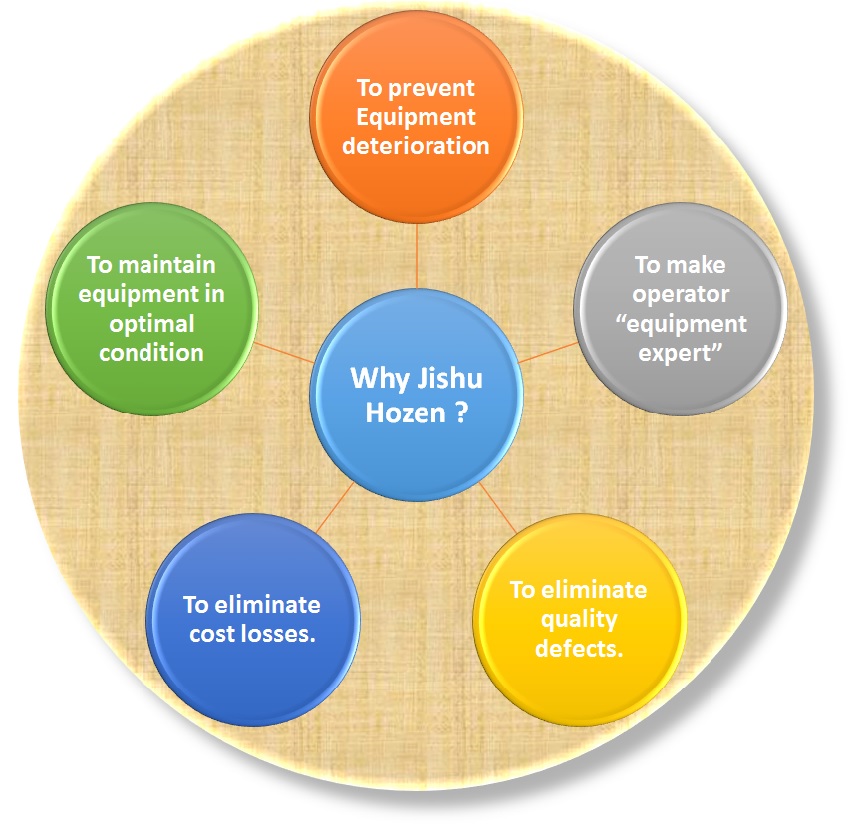

Description Autonomous Maintenance (Jishu Hozen) is one of the most important building blocks in any Total Productive Maintenance (TPM) program. Autonomous Maintenance refers to TPM activities that involve operators in maintaining their own equipment, independent of the maintenance department.

TPM Steps Of Autonomous Maintenance (Jishu Hozen) Poster (3page PDF Document) Flevy lupon.gov.ph

159-slide PowerPoint presentation (PPTX) on TPM: Autonomous Maintenance (Jishu Hozen) with a supplemental Zip archive file document. Autonomous Maintenance (Jishu Hozen) is one of the most important building blocks in any Total Productive Maintenance (TPM) program. Autonomous Maintenance refers to TPM activities that involve operators in maintaining their own equipment, independent of the.

PPT JH Pillar training up to step 02 PowerPoint Presentation, free download ID11532593

7 Steps of Jishu Hozen (Autonomous Maintenance) Pillar in TPM. 7 QC Tools for Process Improvement | PDF | Case Study. 5S in the Workplace | 5S Implementation | 5S Meaning | PDF. Problem Solving Methods | Steps, Process, Examples. Categories. 7 QC Tools (8) Control Chart (3) Difference (9) FMEA (3) General (12) IATF 16949 (4)

Concepts of Business Excellence Concepts of Total Productive Maintenance Topic 6 Steps

The purpose of this paper is to evaluate the contributions of TPM initiatives through Work sampling to achieve the World class OEE which raise the Quality excellence. Hence in sampling study has been conducted to compute the downtime and utilization of the machines and to improve OEE.

Jishu hozen

Autonomous Maintenance TPM: 7 Steps of Autonomous Maintenance (Jishu Hozen) Poster Unlock all preview images: Login Register TPM: 7 Steps of Autonomous Maintenance (Jishu Hozen) Poster (PDF) File Type: 3-page PDF document Secondary File: PowerPoint (PPTX) $20.00

Jishu Hozen Implementation Steps Portrait Wall Sign

2.1 Autonomous Maintenance (JISHU - HOZEN) 7 Let us now study Jishu - Hozen in detail: 2.1.1 What is JISHU - HOZEN? 2.1.1.1 Individually Preserving Related Equipment "I am working on the machine, so it is my responsibility to maintain it" is the main principle in the TPM concept. Many failures can be prevented if operators perform some

TPM Steps Of Autonomous Maintenance (Jishu Hozen) Poster (3page PDF Document) Flevy lupon.gov.ph

The Autonomous Maintenance or Jishu Hozen audit system assesses the progress made by production teams toward achieving the company's TPM goals. The Autonomous Maintenance audit step-by-step checklists are based on the TPM Excellence Framework. The AM audit checklists are especially useful for companies who want to kick-start the AM implementation process and are not quite sure how to define.

Jishu Hozen Implementation Steps Portrait Wall Sign

2. jishu hozen - AM.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site. Open navigation menu. Close suggestions Search Search.. Training on 7 Steps of Jishu Hozen. 6. Gant Chart. 7. Training on 7 Types of abnormalities

TPM 7 Steps of Autonomous Maintenance (Jishu Hozen) Poster (3page PDF document) Flevy

PM & Jishu-Hozen, first step 36 Sumarizing AI / IoT sharing in PM & Jishu-Hozen 37 VI. Training of Jishu-Hozen. 39 Teach and training of basic repair & maintenance. 39 a) Tighten bolt properly. 39 The accident reporting. 39 Training of tightening bolt properly. 41 Aim of the training and target 41 Target persons of training and preconditions 41

Jishu Hozen.ppt Lubricant Reliability Engineering

7 Steps of Jishu Hozen (Autonomous Maintenance) Pillar in TPM 14 Comments What is Jishu Hozen (Autonomous Maintenance)? → The Jishu Hozen is a Japanese word that means autonomous maintenance. → Autonomous Maintenance is a well-defined method for maintaining the machine by the operator rather than the maintenance person.

Jishu hozen

Jishu Hozen, also known as Autonomous Maintenance, is a key pillar of Total Productive Maintenance (TPM) that emphasizes the involvement of operators in equipment maintenance. Jishu Hozen is based on several key principles that, when applied effectively, can lead to increased equipment reliability, reduced downtime, and improved productivity.