N.RAJESHKANNA, CNC MACHINE PARTS & MCODE, GCODE,

M-Codes. - end the program. Pressing ("R" in the Axis GUI) will restart the program at the beginning of the file. - exchange pallet shuttles and end the program. Pressing will start the program at the beginning of the file. Change from Auto mode to MDI mode. Origin offsets are set to the default (like.

Melancholie Ballon Pef laser gcode generator Abgeschafft konservativ Christian

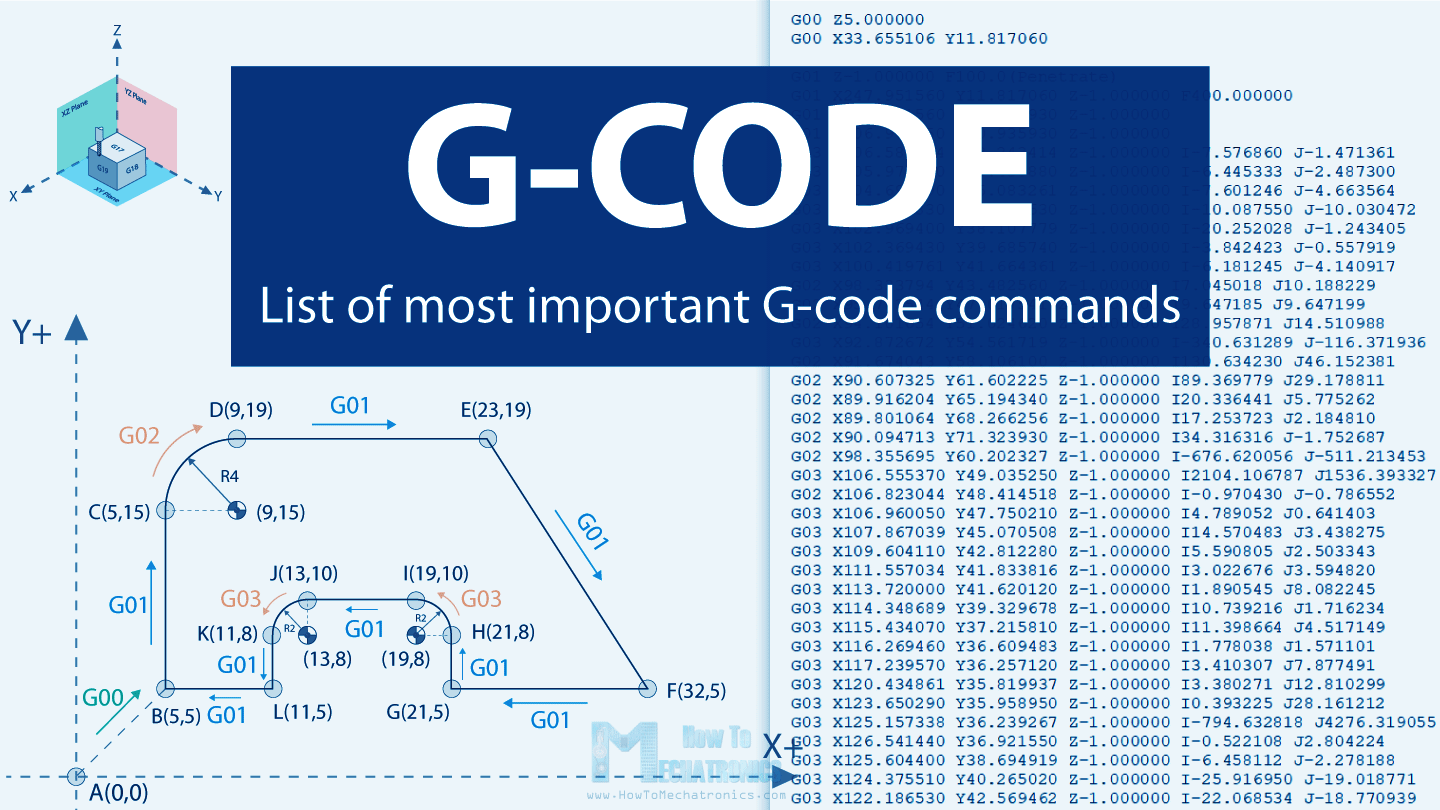

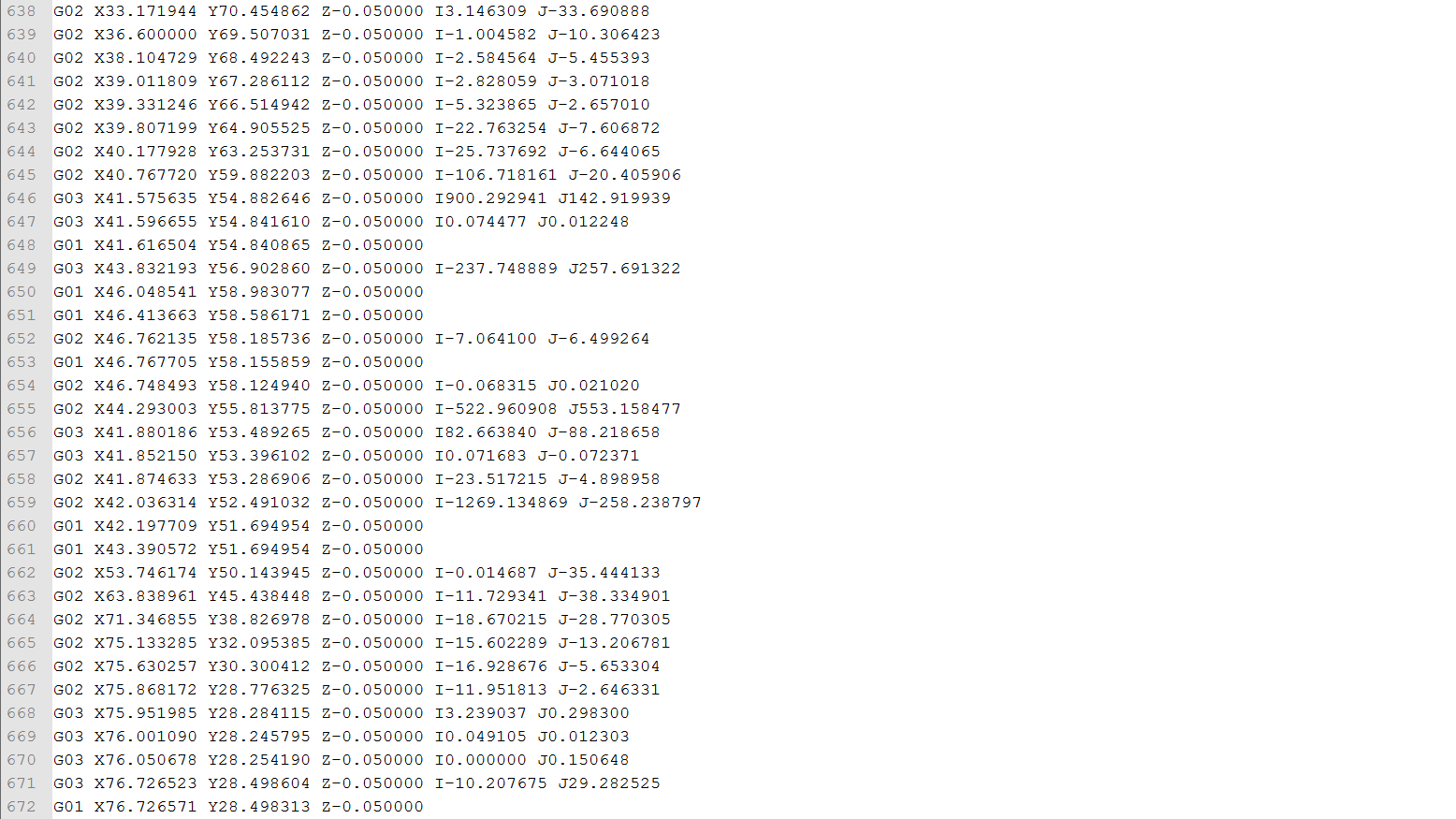

G-Codes. In the G-code prototypes the hyphen () denotes an optional item. is written in a prototype the will often be referred to as the , and so on for any other letter. 5. G2, G3 Arc Move. A circular or helical arc is specified using either (clockwise arc) or (counterclockwise arc) at the current .

cnc befehle, Gelöst Suche nach 4Achse Postprozessor für CNC Graf Seite 2 Autodesk

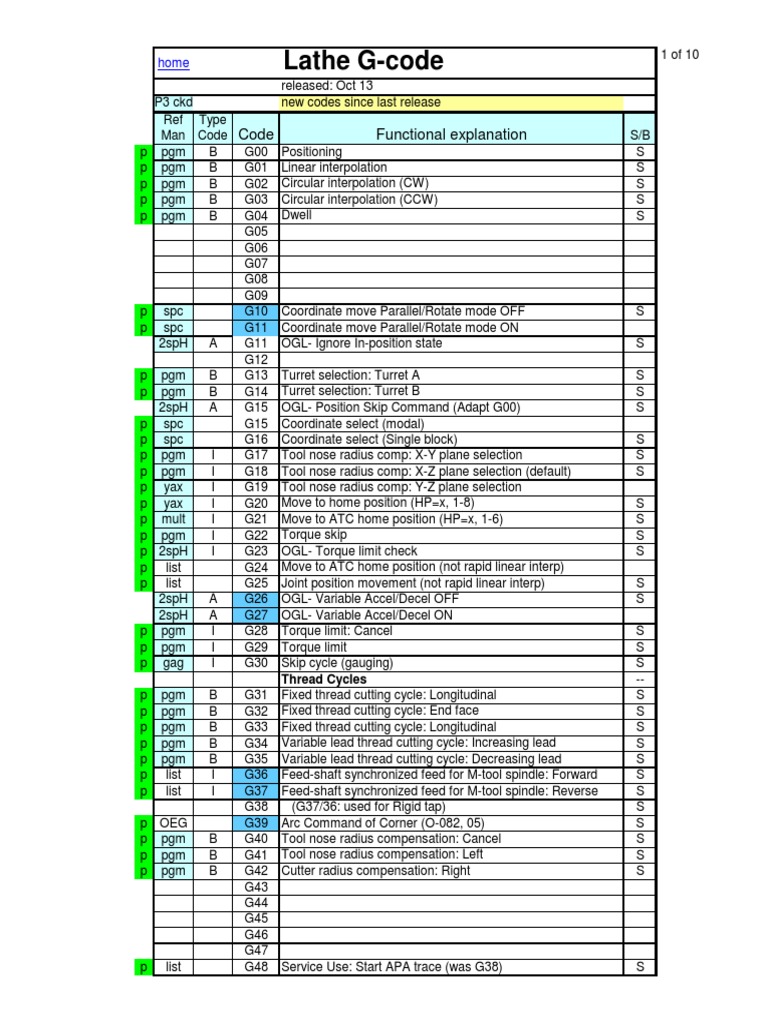

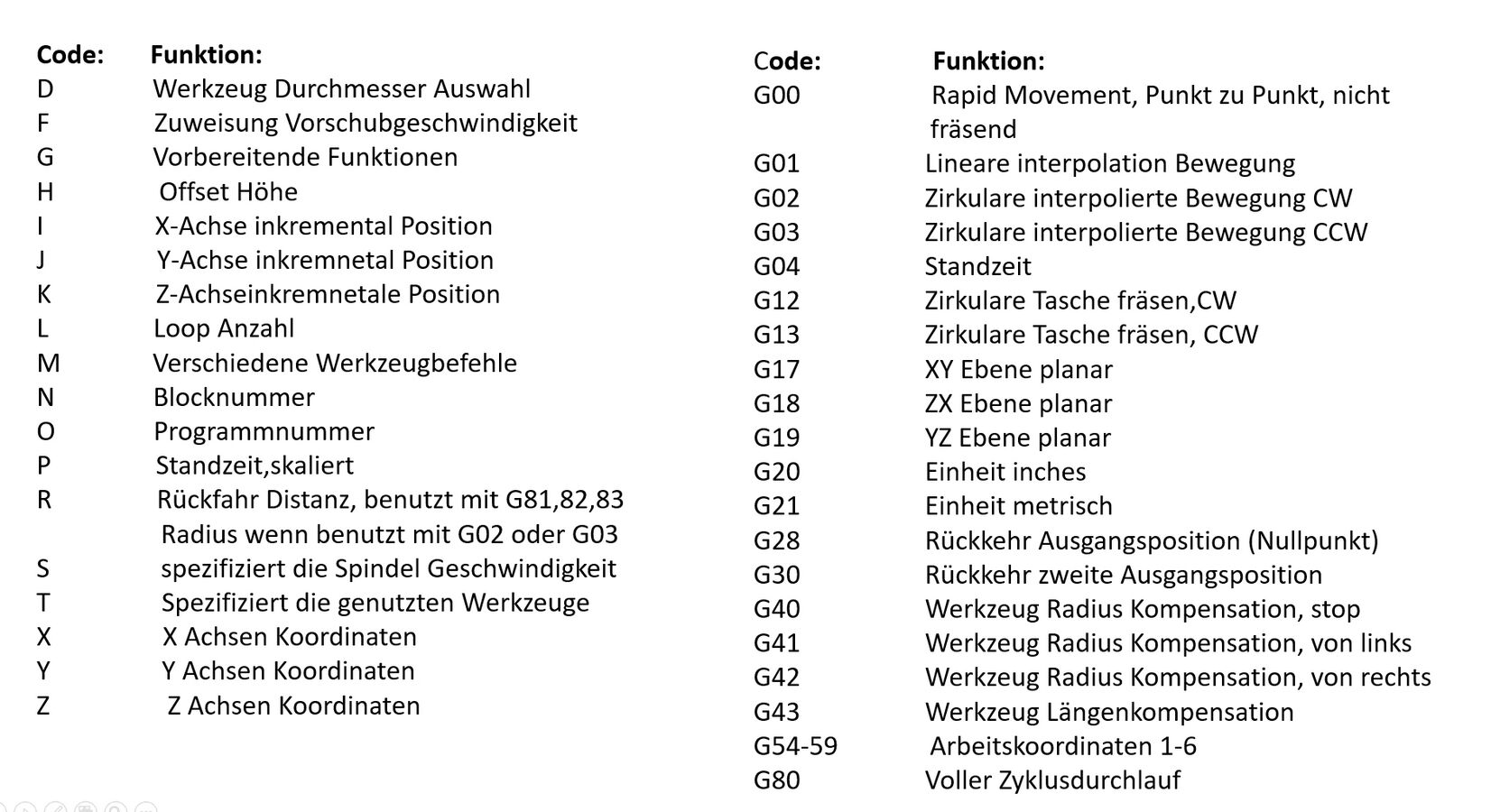

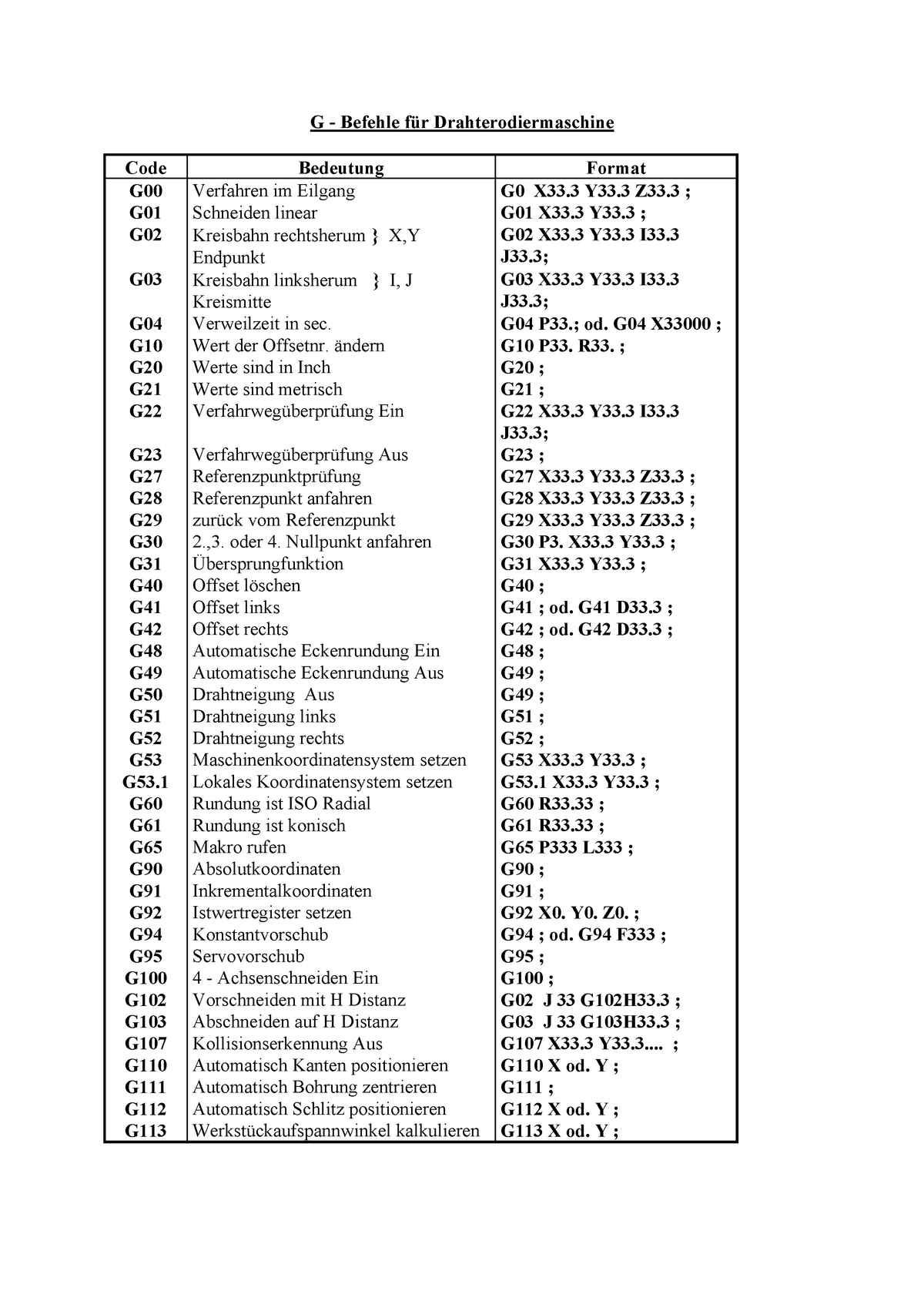

G Codes GSK983M CNC Milling. G Codes GSK983M S/V Drillling & Milling CNC System G Codes GSK983M G Code Function G00 Positioning G01 Linear interpolation G02 Circular interpolation (CW) G03 Circular interpolation (CCW) G04 Dwell….

Free 3d printer gcode files simpsons outdoorret

G-Codes und M-Codes Fräsen. Kreisbewegung von der aktuellen Position (z.B. X20, Y10) hin zu X30, Y25. Der Bogen führt über das Kreiszentrum (Xact - I5) = 25 und (Y25-J0) = 25. Der Startpunkt (also die aktuelle Position) muss dabei auf der Kreisbahn liegen. Alle Achsen fahren auf Punkt 0 (auch evtl.

Basic G Code Part 1 YouTube

M502 (Factory Default) - Resets all configured settings to factory defaults. M503 (Report Settings) - Shows a report of the current settings. M504 (Validate EEPROM Contents) - Validates the EEPROM. Next up, we will be looking into each of these G-Codes separately and in greater detail to understand how they really function and find the.

Genial G Code Befehle

Complete G Code List. List of G-codes commonly found on Fanuc and similarly designed CNC controls. G00 Positioning (Rapid traverse) G01 Linear interpolation (Cutting feed) G02 Circular interpolation CW or helical interpolation CW. G03 Circular interpolation CCW or helical interpolation CCW. G04 Dwell. G10 Programmable data input.

CNC Turning (FANUC) GCode MCode SOLO CAD DESIGNER

Click on the G-code you would like to have more more information about in the columns below, or view one of our reference manuals: Mach 3 G-Code Language Reference: Download. Mach 4 G- and M-Code Language Reference: Download. Search Blog. Categories. Videos - Grinding - Milling - Turning - Waterjet Cutting

An Intro to Gcode and How to Generate It Using Inkscape Norwegian Creations

G03 Y50.0 I10.0 J40.0 F100.0; G01 X50.0; The K is seldom used but is available if an arc using the Z axis is needed. When using G02 with G01 and G03 (Counter clockwise arc) any shape can be machined. These three G Codes are the foundation of G Code programming and are the three you will use when cutting material.

FANUC G Code of Lathe Machining Drilling Free 30day Trial Scribd

G-Code Codes. Below are some common individual codes, that when combined, guide a machine's movement. G00: Rapid positioning. This code causes the machine to operate at a high speed. G01: Linear interpolation. The machine will move in a straight line, performing the appropriate machining (milling, cutting, etc).

G Code List Okuma PDF Metalworking Nature

2. Put together a simple header format that you plan to use for your g-code programming. Use it to create a simple do-nothing program that can serve as the initial template when you create a new g-code file. 3. If you use a CAM program, investigate what its options are for headers in the g-code file it posts. 4.

GCode Example 6 Easy GCode Examples to Begin With All3DP Computer Numerical Control, Basic

(Some G-Code Blocks Go Here to Be Repeated Each Loop) #100 = #100 + 1 (Increase #100 by 1 each iteration of the loop) END1. That's all there is to it. We use g-code variable #100 as a counter. It starts out as 1, and we add 1 to it each time around the loop. So long as it is less than or equal to 5, we keep doing the loop.

SolidWorksCAM HSHL Mechatronik

G-code is the language of 3D printers, but how well do you know it? In this tutorial, you will learn the main commands and how to use them effectively. Whether you want to control the temperature, the speed, the movement, or the extrusion, this guide will help you master the basics of G-code. Plus, you will find a handy list of the most common commands for quick reference. Don't miss this.

cnc befehle, Gelöst Suche nach 4Achse Postprozessor für CNC Graf Seite 2 Autodesk

with g-code. That's what our G-Code Editor software is all about. It simulates g-code as well as decoding it for you. You can try out different g-codes and see visually what they do. Experimenting is one of the best ways to get a good grasp of g-code. At the end of each section is a Quiz to test your skills. Take the quiz and use the links on the

Genial G Code Befehle

G02. Motion. Clockwise circular arc at (F)eedrate. XYZ of endpoint IJK relative to center R for radius. G03. Motion. Counter-clockwise circular arc at (F)eedrate. XYZ of endpoint IJK relative to center R for radius.

Mazak M Kodları

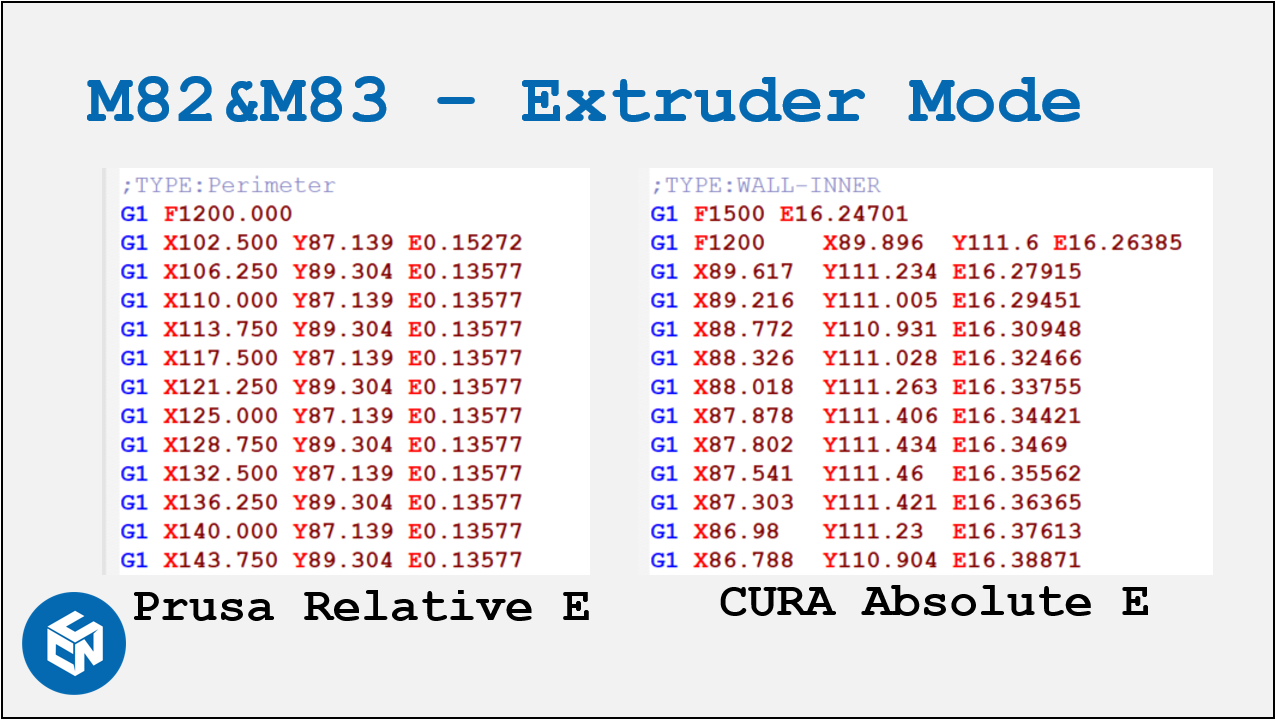

This page tries to describe the flavour of G-codes that the RepRap firmwares use and how they work. The main target is additive fabrication using FFF processes. Codes for print head movements follow the NIST RS274NGC G-code standard, so RepRap firmwares are quite usable for CNC milling and similar applications as well.See also on Wikipedia's G-code article.

G code

Instead, Klipper prefers human readable "extended G-Code commands". Similarly, the G-Code terminal output is only intended to be human readable - see the API Server document if controlling Klipper from external software. If one requires a less common G-Code command then it may be possible to implement it with a custom gcode_macro config section.